Tetrakis Palladium , 14221-01-3 , C72H60P4Pd

Catalysts are compounds that accelerate chemical reactions by lowering the energy barrier between reactants and products. They not only save energy, but also help produce pure products instead of mixtures.

Chemists use a wide variety of catalysts, many of which are metal-based. These metals, such as gold, nickel, and palladium, iridium, ruthenium, platinum, are located in the middle of the periodic table in the long d section part of the elements.

Properties

Precious metal catalysts exhibit unique properties in our lives. Depending on the nature of the reaction, they have incompletely filled d orbitals to lend or retrieve electrons from the reagent. Therefore, precious metals always exhibit high activity and selectivity in catalysis. Besides, precious metal catalysts are also stable and not easily oxidized to form oxides. The high activity and high thermal stability of precious metal catalysts allow us to use them in a wide range of applications. The catalyst only changes the rate of the chemical reaction and does not participate in the reaction itself.

How it works

Precious metal catalysts are catalysts consisting of highly dispersed nanoscale particles of precious metals loaded on high surface area substances such as carbon, silica and alumina.

These metals are good catalysts because they can exist in two or more different ionic forms in a compound, and in some reactions, iridium will act as a catalyst and lower the energy barrier by changing from one oxidation state to another. However, when the reaction is complete, it changes back to its original state in order to start again. Although the catalysts change during the reaction, they are not used up during the reaction.

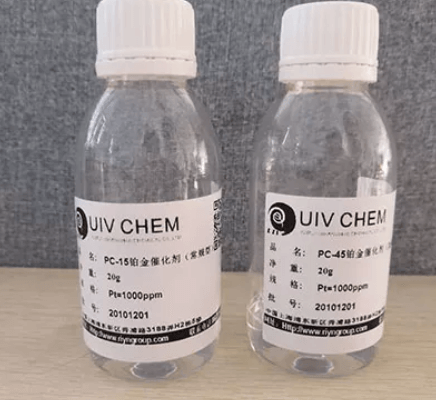

Platinum-divinyltetramethyldisiloxane complex

Their uses

Catalysts are used in many industrial processes, such as breaking down long chain hydrocarbon molecules into smaller molecules in refining petroleum, helping synthesize ammonia in the reaction of hydrogen and nitrogen, and synthesizing drugs for the pharmaceutical industry.

Most cars are now equipped with catalytic converters to reduce harmful emissions from the engine. They use small particles of precious metals (such as platinum and rhodium, which are also precious metal catalysts) embedded in a ceramic honeycomb. These small particles provide a large surface area - which then effectively catalyzes the chemical reactions that remove exhaust gases.

Other industries such as agrochemicals, petrochemicals, chemicals, environmental and materials science, also use transition metals as catalysts on a large scale.

Precious Metal Recovery

Many reactions are catalyzed by a variety of non-homogeneous or homogeneous precious metal catalysts. As precious metal catalysts are a very scarce resource, the recovery and refining processes of precious metal catalysts play an important role in this field.

All spent catalysts are contaminated to some extent with unwanted materials and elements such as sulfur, carbon, moisture and solvents.

Usually, the recovered waste is first pre-recycled and combusted. This step ensures that the spent catalyst is free of accumulated contaminants and that the material is free flowing for maximum sampling accuracy. Pre-combustion can be performed at a precious metal refinery or elsewhere.

Afterwards, the precious metal catalyst refinery recovers the platinum group metals and rhenium by dissolving the spent catalyst in a strong base or acid. This hydrometallurgical recovery process is commonly referred to in the industry as "digestion".

UIV chem offers a wide range of precious metal catalysts, if you need one, please contact us for a quote. If you are not sure what catalyst to choose for your production, please feel free to call us to speak with one of our expert chemists.