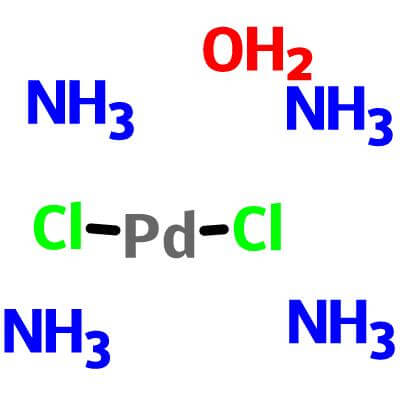

Tetraamminepalladium (II) Chloride

| Identification | ||

| Name |

|

Tetraamminepalladium (II) chloride |

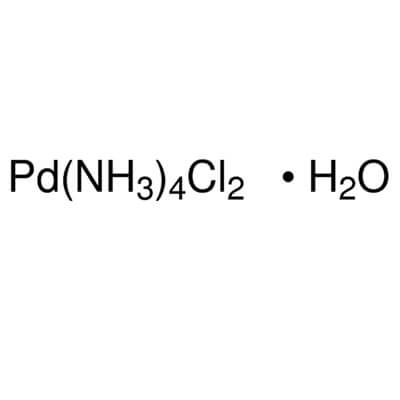

| Synonyms |

|

Tetraamminepalladium(II) chloride monohydrate;

Pd(NH3)4Cl2·H2O |

| Molecular Formula |

|

Pd.(NH3)4.Cl2 |

| Molecular Weight |

|

233.35 |

| CAS Registry Number |

|

13933-31-8 |

| Properties | ||

| Density |

|

1.91 |

| Melting point |

|

120 ºC (dec.) |

| Appearance |

|

Light yellow powder |

|

Pd content |

|

43% |

| Safety Data | ||

| Hazard Symbols |

|

Xi |

| Risk Codes |

|

R36/37/38 |

| Safety Description |

|

S26;S37/39 |

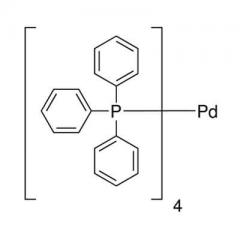

Tetraamminepalladium (II) chloride Application:

Palladium(II), an important palladium compound, is widely used in chemical catalysis and electroplating industry. It is the main raw material for palladium plating and a new type of electroplating main salt. Its electroplating efficiency is high, clean and environmentally friendly, and it has been widely used In the electronics industry. In addition, due to its good water solubility and relatively stable chemical properties of the solution, dichlorotetraamine palladium(II) can also be used as a precursor compound for a supported palladium catalyst.

Tetraamminepalladium (II) chloride preparation:

A preparation method of dichlorotetraamine palladium solid crystals, comprising the following steps:

(1) Acid immersion dissolution: soak palladium flakes or palladium powder with aqua regia 1g:4mL at 70℃ for 90min;

(2) Hydrochloric acid to drive nitrate: Heat the solution of step (1) in the reaction kettle to 1/2 of the original volume, under boiling conditions, add 30% concentrated hydrochloric acid dropwise while heating until no reddish brown gas is generated , Stop heating and cool to 75℃;

(3) Ammonia water complexation: slowly add 25% ammonia water to the solution of step (2), dropwise add to the solution system PH=8 and then stop adding the ammonia water; the ammonia dripping process maintains uniform stirring and stirring speed 100r/min. After the reaction, let stand and cool to 20°C, filter out insoluble impurities, wash the filter residue with pure water until the pH of the filtrate is 6, and the filter residue can be recycled;

(4) Acidification: Add 30% concentrated hydrochloric acid dropwise to the filtrate obtained from step (3) filtration, add dropwise to the solution system PH=1 and then stop adding the concentrated hydrochloric acid, filter after cooling, and the temperature after cooling is 20°C , To obtain palladium yellow (dichlorodiamine palladium), wash the palladium yellow once with a 1% hydrochloric acid solution at a temperature of 20°C, and then wash the palladium yellow with DI water twice, and the filtered filtrate is subjected to wastewater treatment;

(5) Dissolving in ammonia water: transfer the palladium yellow obtained by filtration in step (4) to a conversion tank, add 25% ammonia water dropwise to dissolve the palladium yellow, and cool to 25°C;

(6) Dehydration crystallization: Add a dehydrating agent (absolute ethanol) to the solution of step (5) in the ratio of Pd: dehydrating agent = 1:3 for dehydration crystallization. The operating temperature of the dehydration crystallization process is 20°C, and the crystallization process is maintained Stir at a uniform speed of 110 r/min, filter out solid crystals after the reaction, wash the solid crystals twice with a dehydrating agent, drain the solid crystals by vacuum filtration, and treat the filtered filtrate for wastewater treatment;

(7) Drying: The solid crystals obtained in step (6) are dried under vacuum drying conditions at 40°C, and the vacuum negative pressure value is 0.08Mpa. After drying to constant weight, take them out to obtain clean solid crystals of palladium dichlorotetraamine salt. The yield was 93%.

Tetraamminepalladium (II) chloride Uses:

Used as precious metal electroplating reagents and additives. It is a raw material for synthesizing a variety of palladium compounds and is used in large quantities to prepare palladium plating bath solutions.